Professional China Juice Bag In Box - BIB Bag In Box Liquid Wine Beverage Plastic Packaging Bag – OK Packaging

Professional China Juice Bag In Box - BIB Bag In Box Liquid Wine Beverage Plastic Packaging Bag – OK Packaging Detail:

description

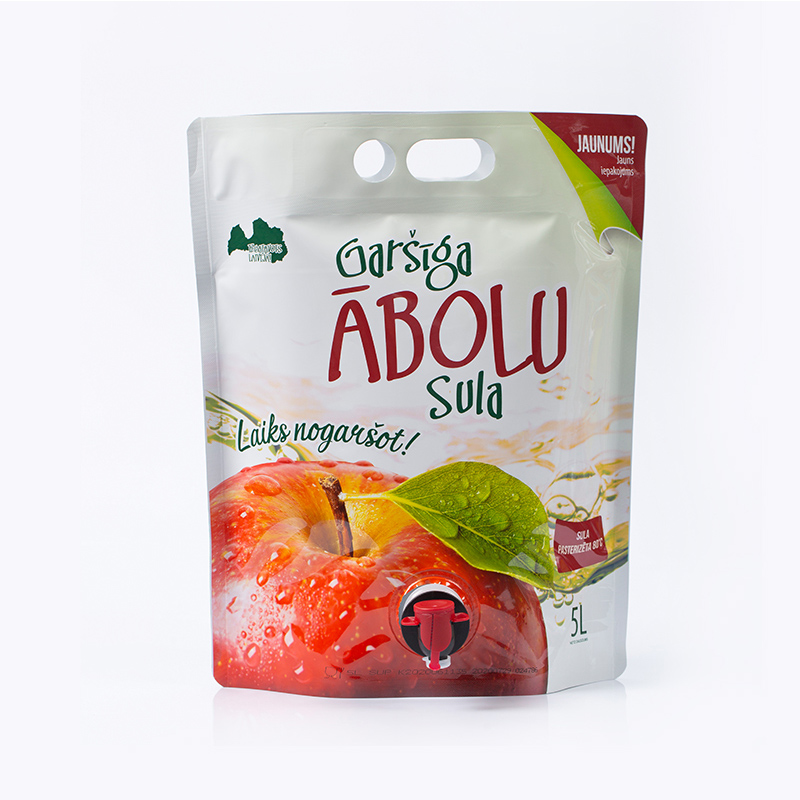

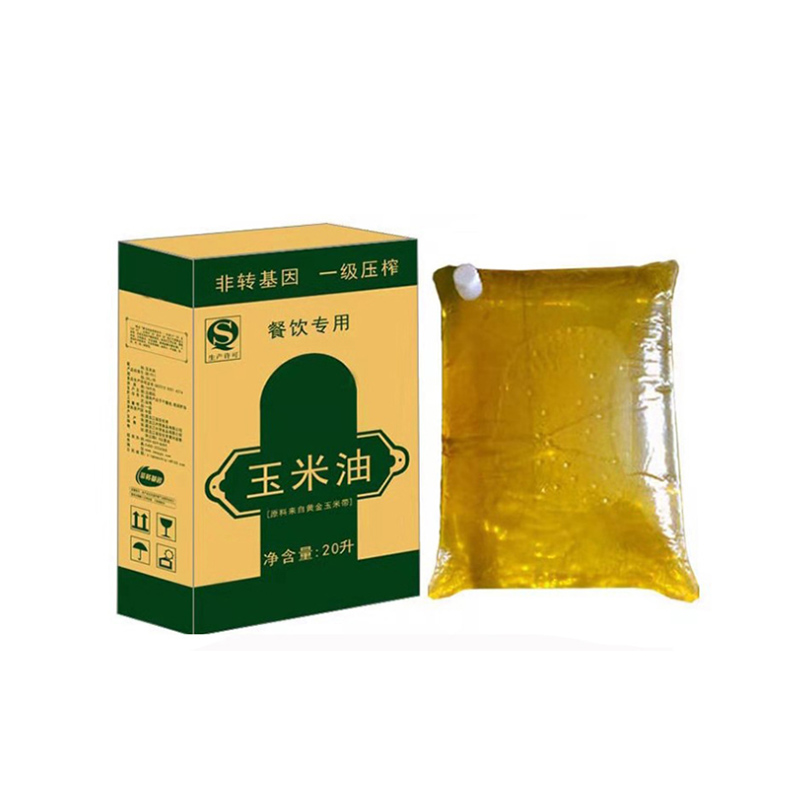

A bag-in-box is constructed of a flexible inner bag made of multiple layers of film and a sealed tap switch and a carton.

Inner bag: made of composite film, using different materials to meet the needs of different liquid packaging, can provide 1-20 liters aluminum foil bag, transparent bag, single or continuous roll standard products, with standard canning mouth, can be sprayed with codes , can also be customized size.

Uses: Bag-in-box packaging is widely used in fruit juice, wine, drinks, mineral water, edible oil, food additives, industrial pharmaceuticals, medical reagents, liquid fertilizers, etc.

Product Details and advantage:

1. Made of non-toxic plastic, with acid and alkali resistance, high temperature molding and radiation sterilization. Sterile, non-toxic and odorless.

2. It is foldable, light in weight, easy to store and transport, and reduces the cost of material storage and transportation and packaging.

3. Environmentally friendly and hygienic, easy to recycle, just separate the box and the inner bag to recycle.

4. The product use period can be close to the shelf life period, and the shelf life period is longer. The wine and juice stored in the bag in box can be sealed for 12-14 months, and can be stored for 2 months after opening.

5. This packaging form has strong competitiveness in 1-20 liters volume packaging.

6. A variety of inner bag film materials and faucet switches greatly expand the types and application fields of packaging liquids.

7.Suitable for gift packaging without preservative additives and refrigerated storage

Features

Multi layer high quality overlapping process

Multiple layers of high-quality materials are compounded to block moisture and gas circulation and facilitate internal product storage.

Butterfly valve

The valve port can be opened or closed at any time, which is convenient for use at any time.

Soft material

It is foldable, light in weight, easy to store and transport。

More designs

If you have more requirements and designs, you can contact us

Our Certificates

Product detail pictures:

Related Product Guide:

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for Professional China Juice Bag In Box - BIB Bag In Box Liquid Wine Beverage Plastic Packaging Bag – OK Packaging , The product will supply to all over the world, such as: Georgia, Japan, Madrid, Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.