Custom Plastic BIB Bag In Box 3l 5l 10l 20l Liquid Wine Beverage Aseptic Packaging Aseptic Bag In Box With Valve

Custom Plastic BIB Bag In Box 3l 5l 10l 20l Liquid Wine Beverage Aseptic Packaging Aseptic Bag In Box With Valve Description

Bag-in-box is a new type of packaging, which is convenient for transportation, storage, and saves transportation costs. The bag is made of aluminized PET, ldpe, and nylon composite materials. Aseptic sterilization, bags and faucets are used in conjunction with cartons, the capacity has now developed to 1L to 220L, and the valves are mainly butterfly valves.

Bag-in-box packaging is widely used in fruit juice, wine, fruit juice drinks, mineral water, edible oil, food additives, industrial pharmaceuticals, medical reagents, liquid fertilizers, pesticides, etc.

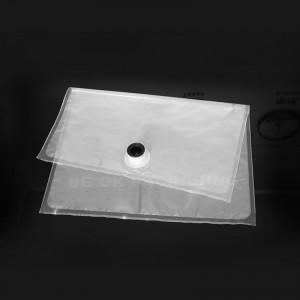

A bag-in-box is constructed of a flexible inner bag made of multiple layers of film and a sealed tap switch and a carton.

Inner bag: made of composite film, using different materials to meet the needs of different liquid packaging, can provide 1--220 liters aluminum foil bag, transparent bag, single or continuous roll standard products, with standard canning mouth, can be sprayed with codes , can also be customized.

The inner bag can be customized transparent or aluminum plating and other colors at the same time according to the customer's products, different requirements to carry different valves, the outer box design can be customized, provide design services and professional guidance.

Custom Plastic BIB Bag In Box 3l 5l 10l 20l Liquid Wine Beverage Aseptic Packaging Aseptic Bag In Box With Valve Features

Custom valve

The edges are heat-sealed with high strength.